[ad_1]

Manufacturing ideas which might be being developed in Arizona State College labs will quickly be on a direct pathway to trade utility — additionally referred to as tech switch — a essential breakthrough in advancing the manufacturing trade in Arizona.

This chance has been made attainable by way of efforts in ASU’s Manufacturing, Automation and Data Engineering, or MADE, Science and Know-how Heart. STCs are supported by Arizona’s New Economy Initiative, an funding in ASU’s project to drive the state’s future financial progress and resiliency by way of engineering and expertise innovation and coaching.

Designed to leverage ASU’s school experience and its expertise in establishing and sustaining trade partnerships, the MADE STC, positioned at ASU’s Polytechnic campus, facilitates collaboration to generate novel manufacturing applied sciences, resulting in new merchandise which have the potential to influence trade operations and U.S. manufacturing competitiveness.

MADE’s first two tasks had been submitted by PADT, Inc. — a number one supplier of numerical simulation, product growth and 3D printing services and products in Tempe, Arizona.

The primary challenge goals to develop new applied sciences to recycle and upcycle unused supplies to optimize additive manufacturing processes. The second is creating AI-based software program capabilities that can predict the manufacturability of a brand new product design. Though completely different, each tasks search to cut back prices, eradicate waste and are on a trajectory to be fast-tracked to commercialization.

Re-establishing U.S. management in superior manufacturing to maintain tempo with present and future expertise calls for is likely one of the major motivators behind tech-transfer initiatives like this one.

“Over the previous few years, Arizona has seen a major infusion of superior manufacturing throughout all industrial sectors,” says Binil Starly, the inaugural director of the School of Manufacturing Systems and Networks, one of many seven colleges within the Ira A. Fulton Schools of Engineering at ASU. “STCs present a mechanism for corporations to faucet into college expertise, infrastructures and experience.”

A collaborative funding into the way forward for manufacturing

PADT’s proposed tasks aligned nicely with MADE’s main thrust areas, which embrace course of science and engineering, robotics and automation, and knowledge analytics, cyber and AI.

The scope of each tasks was decided by PADT’s principal and co-owner Rey Chu. Chu manages the corporate’s 3D printing and additive manufacturing providers and likewise serves because the challenge supervisor for the 2 tasks. He and his workforce of two different PADT engineers had been paired with ASU school, enabling a collaborative area for concepts to remodel into ideas that may ultimately be commercialized.

“We now have labored with ASU for the previous 20-plus years, from capstone tasks to graduate pupil analysis tasks and people tasks are vital as a result of they’re designed to show college students and publish analysis papers,” Chu says. “However, the STC tasks are completely different as a result of each events are contributing the funding and technical experience with the purpose of commercialization and accelerating the expansion of the additive manufacturing panorama.”

MADE debuts two tasks from its portfolio

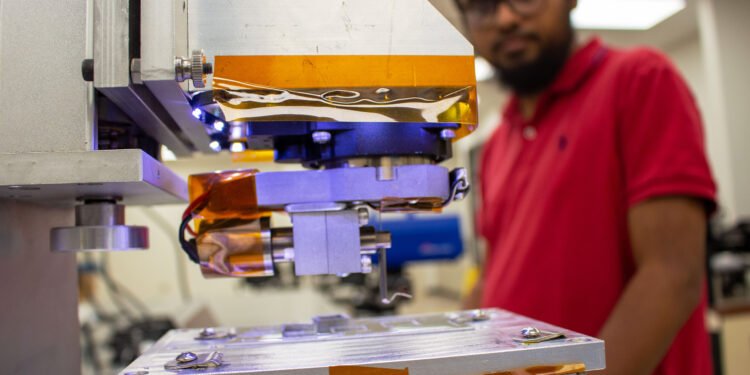

Affiliate Professor Keng Hsu within the College of Manufacturing Programs and Networks will lead one of many two tasks in his Manufacturing Innovation Lab. He and graduate analysis affiliate M. Faisal Riyad and postdoctoral analysis scholar Pu Han will work collectively on this effort.

The 12-month challenge, focused to influence the aerospace trade, will purpose to develop expertise that may flip unused supplies into helpful feedstock for different operations like typical MIG welding and directed vitality deposition, or DED, metallic additive manufacturing expertise.

“Presently, waste or out-of-spec feedstock supplies undergo both pricey or extremely energy-intensive processes for recycling or are saved at warehouses with no plans for additional processing,” Hsu says. “This expertise will create a course of that’s extra vitality environment friendly and value efficient, less complicated, safer and extra accessible.”

Each Hsu and Chu say a multi-phase course of to commercialization is projected.

“To take a expertise like this to commercialization, we’re three to 5 years of primary and engineering analysis and growth,” Hsu says. “On prime of this, we’ll then deal with engineering validation and productization.”

Hsu and his workforce purpose to “acquire as a lot feasibility data as attainable in section one” and primarily based on what they be taught, transfer into section two and past.

The second of the 2 tasks is being led by Andi Wang and Hyungwoong Ko, each assistant professors additionally within the College of Manufacturing Programs and Networks. The challenge will contain a workforce of scholars, starting from undergraduate contributors within the Fulton Undergraduate Research Initiative to doctoral candidates.

Over the course of 18 months, Wang and Ko will use AI-based software program capabilities to “set up an evaluation course of that mechanically determines a product design’s chance of success, or manufacturability, earlier than the manufacturing course of begins,” Wang says.

This “additive manufacturing advisor” will cut back price and waste brought on by trial and error and has the potential to learn PADT’s additive manufacturing consulting service space.

“The AI fashions primarily based on real-world knowledge can predict the extent of floor roughness, flatness or straightness. It additionally predicts the porosity or different high quality points of additive manufacturing merchandise resembling lattice and topology-optimized buildings,” Wang and Ko write. “Utilizing predictive data, the practitioner can choose the suitable machines or supplies and modify their designs for high-value additive manufacturing purposes, resembling biomedical and aerospace purposes, earlier than a big batch of defects is fabricated. This analysis seeks to seek out AI-driven options that may make anticipatory predictions and to realize born-qualified merchandise past conventional in-situ monitoring and management and ex-situ analysis.”

Chu says these are two areas that PADT sees demand for within the trade.

“Our purpose in collaborating in these [STC] tasks is to essentially strengthen the Phoenix and Arizona manufacturing base,” he says.

The long run is now

Starly anticipates that these two tasks are solely the start and envisions MADE initiating a domino impact of alternative and attracting extra funding from personal and federal sources.

“An end result past the technical success of the STC tasks is to construct relationships with corporations, develop human capital and allow new superior manufacturing expertise ecosystems connecting small, medium and enormous companies,” he says.

Organizations curious about collaborating with an ASU STC can accomplish that by submitting a proposal by Friday, December 16, 2022.

[ad_2]

Source link